When the customer calls, we act. So even when the project does not involve a vessel somewhere around the world, yet the engine does match with what we can fix, we will!

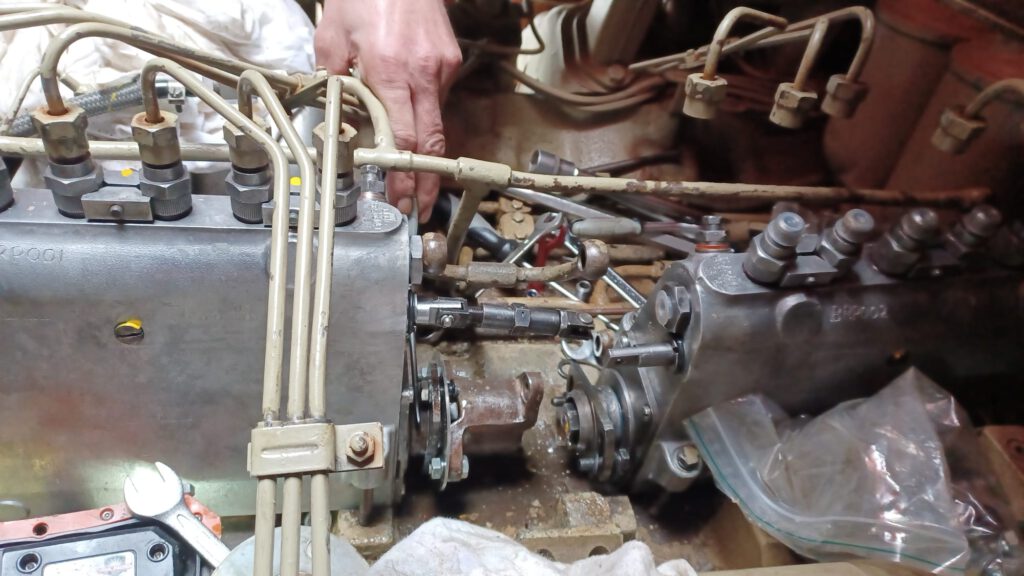

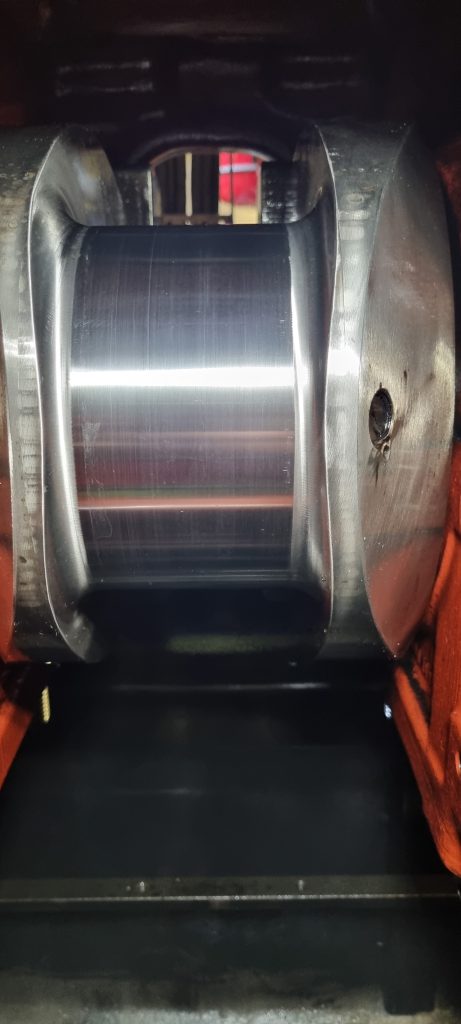

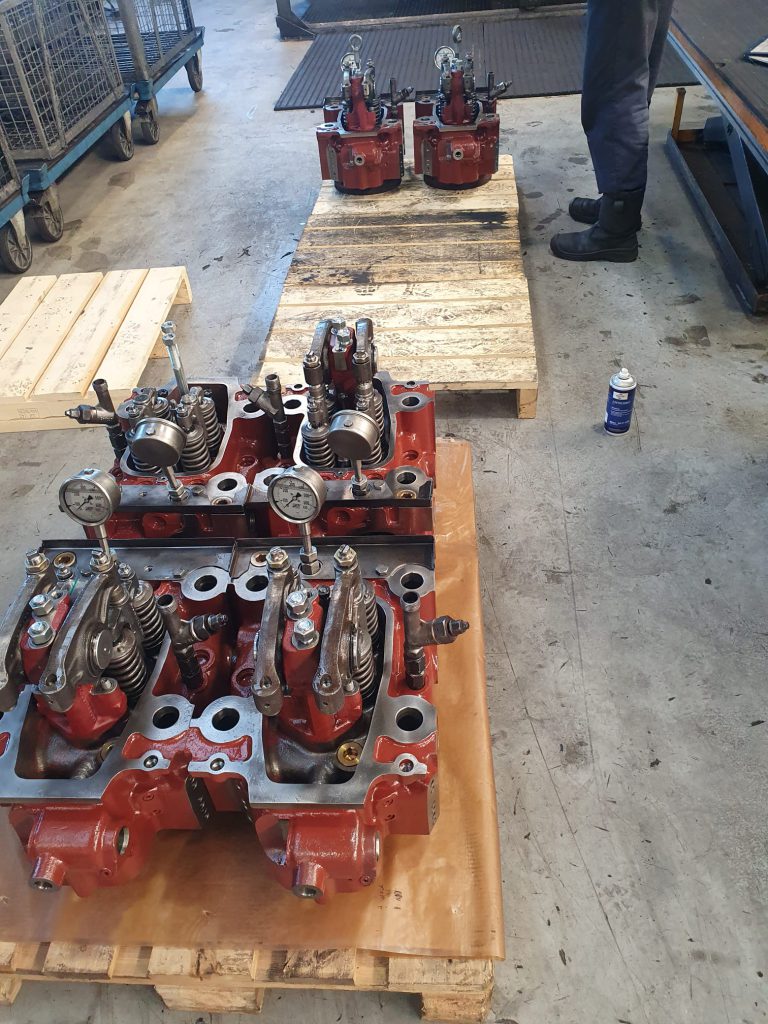

So this gorgeous locomotive O&K MC 14 N from 1963 in Rotterdam Europoort was having fuel system issues in its #DEUTZ716 engine and with that, we know our way.

We are there when our clients need us, even if it does not seem right at first glance.

#MarineTechnics

#Deutz

#Deutz716

#Happycustomer

#Europoort